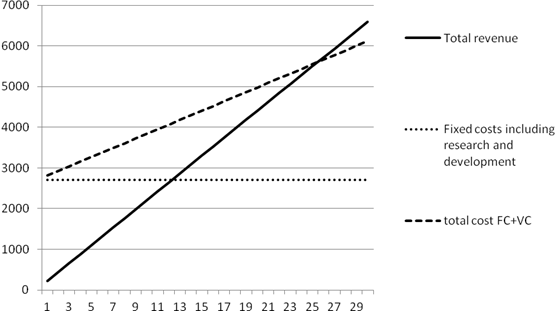

Batch manufacturing methods have been found to be the most appropriate, due to the relatively small numbers in disability sports markets. An economic batch quantity can be calculated once the overhead and set up costs (which are fixed) are added to the unit manufacturing costs (which are variable). A break-even point is achieved when the profit per unit made can repay the fixed and variable costs.

Many assistive technology products are made in very small batch quantities, with high cost associated with delivery of the product. Delivery costs are not shown in example chart. Normally, this may double the retail cost from the manufacturing costs shown. These costs are often unseen by the purchaser. Those involved in raising funds for charitable support groups are not always aware of reasons behind this cost. It is something a designer and manufacturer have to take time to explain to all stakeholders to ensure they know their funds are being appropriately spent.

Useful links

Torrens, GE (2011) Universal Design: empathy and affinity. In Karwowski, W, Soares, M, M, Stanton, A, N, Eds, (ed) Handbook of Human Factors and Ergonomics in Consumer Products, CRC Press, pp.233-248 Available at: (http://www.crcnetbase.com/doi/abs/10.1201/b10950-19), Accessed: [23/09/015]